KAIST Achieves Ultra-High Temperatures with 0.02-Second Light Pulse, Boosting Hydrogen Production Efficiency Sixfold

- Input

- 2025-10-20 09:30:13

- Updated

- 2025-10-20 09:30:13

Recently, developing efficient and cost-effective methods to produce clean energy sources such as hydrogen has become a major research focus. One key area is the rapid synthesis of high-performance catalyst materials using minimal electricity. Researchers at the Korea Advanced Institute of Science and Technology (KAIST) have developed a platform technology that uses a 0.02-second burst of light to achieve ultra-high temperatures of 3,000°C, enabling the efficient production of hydrogen catalysts. As a result, energy consumption was reduced to just one-thousandth of previous methods, while hydrogen production efficiency increased by up to six times.

On the 20th, KAIST announced that a research team led by Professor Kim Il-Du from the Department of Materials Science and Engineering and Professor Choi Sung-Yool from the School of Electrical Engineering developed a synthesis platform called 'Direct-contact photothermal annealing.' This method allows for the synthesis of high-performance nanomaterials simply by briefly exposing them to intense light.

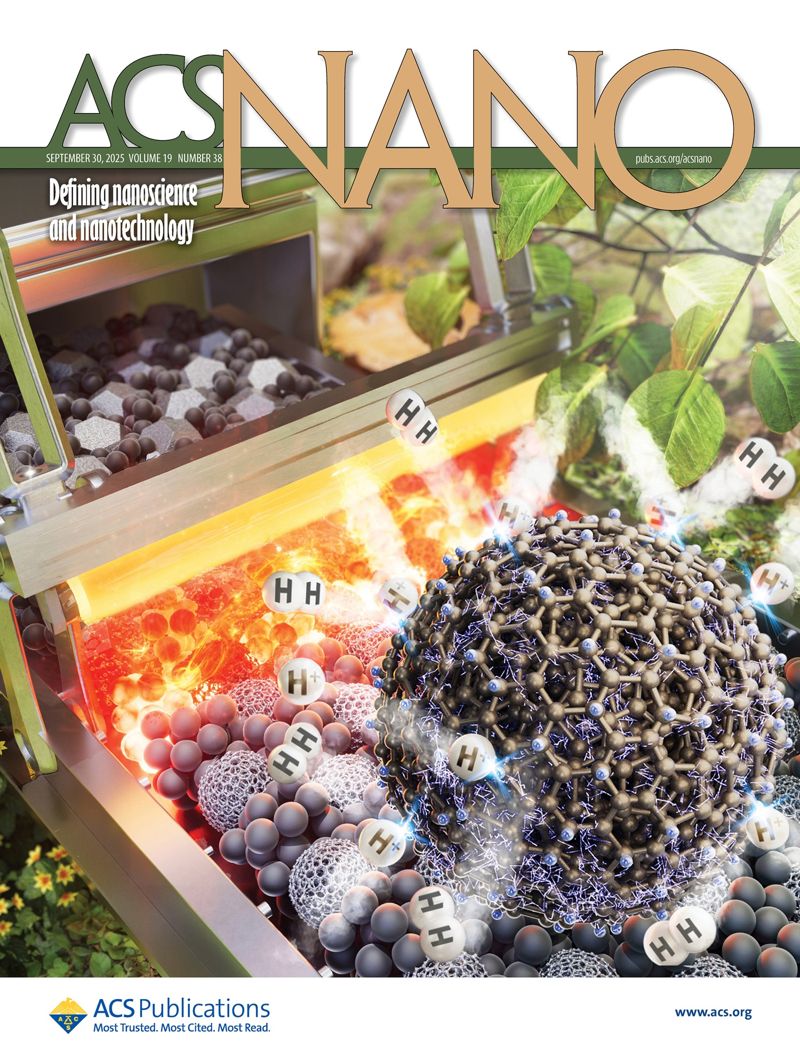

The team developed a catalyst synthesis technique that creates an instantaneous ultra-high temperature of 3,000°C with a very short (0.02-second) light pulse. Using this thermal energy, they successfully converted hard-to-react nanodiamond into a new, highly conductive carbon material known as carbon nano-onion, which is well-suited for use as a catalyst. Compared to conventional wire-based thermal annealing processes, this approach reduced energy consumption to one-thousandth and shortened processing time by several hundred times.

Notably, the process also enabled the attachment of individual metal atoms to the surface of the carbon nano-onion, providing catalytic functionality. In other words, this catalyst platform technology not only transforms the structure through light exposure but also imparts functionality to the material in a single step. Carbon nano-onion is an ultra-fine spherical material composed of multiple layers of carbon atoms, resembling an onion, and is ideal for supporting catalysts due to its excellent electrical conductivity and chemical resistance.

The research team confirmed that nanodiamond was converted into carbon nano-onion in just 0.02 seconds, and molecular dynamics simulations verified that this process is physically feasible.

This platform is considered innovative because it enables both the synthesis of carbon nano-onion and the attachment of single-atom catalysts in a single step. Using this technology, the team successfully synthesized eight types of high-density single-atom catalysts, including platinum (Pt), cobalt (Co), and nickel (Ni). The platinum single-atom catalyst–carbon nano-onion developed by the researchers produced hydrogen with six times greater efficiency than conventional methods, while requiring much less of the expensive metal.

Professor Kim Il-Du stated, “We have implemented the direct-contact photothermal annealing technique for the first time, achieving temperatures up to 3,000°C in less than 0.02 seconds by irradiating with intense light. This ultra-fast, integrated process for synthesis and single-atom catalyst functionalization reduces energy consumption by more than 1,000 times compared to conventional thermal annealing. We expect it will accelerate commercialization in various fields such as hydrogen energy, gas sensors, and environmental catalysts.”

The research findings were published as a supplementary cover paper in the September issue of ACS Nano, a leading international journal in the fields of nanoscience and chemistry, published by the American Chemical Society (ACS).

jiany@fnnews.com Yeon Ji-an Reporter