POSCO Future M, Successful Development of Ultra High Nickel and High Voltage Mid Nickel Cathode Materials

- Input

- 2025-08-21 14:16:37

- Updated

- 2025-08-21 14:16:37

From Entry to Premium Electric Vehicles... Completion of Cathode Material Portfolio

Responding to Future Mobility with High Power Usage such as UAM and Autonomous Driving

Responding to Future Mobility with High Power Usage such as UAM and Autonomous Driving

[Financial News] POSCO Future M has strengthened its strategy to penetrate the premium electric vehicle market and has established a cathode material portfolio that can respond to both the standard and entry electric vehicle markets.

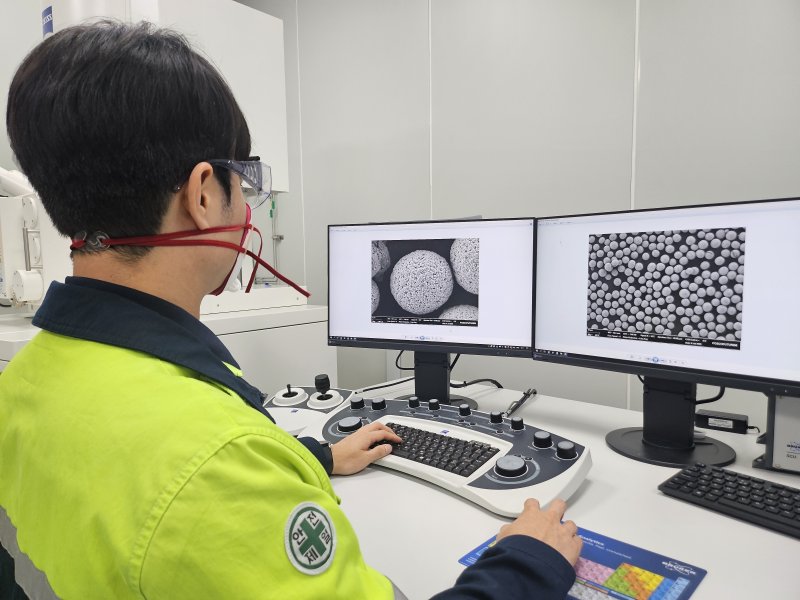

POSCO Future M announced on the 21st that it has succeeded in the pilot development of ultra high nickel cathode materials for premium electric vehicles and high voltage mid nickel cathode materials.

POSCO Future M is currently producing and supplying premium cathode materials centered on high nickel cathode materials (N8x) with a nickel content of over 80%. By mass-producing and supplying the newly developed materials, it is expected to further strengthen its business competitiveness in the cathode material market by responding to various customer demands.

The ultra high nickel cathode material is a premium material that maximizes driving distance by increasing energy density through a nickel content of 95% or more. It is being developed for supply to premium electric vehicles in major advanced markets such as the United States and Europe, as well as to urban air mobility (UAM), which is gaining attention as future transportation. As the use of artificial intelligence (AI) in mobility expands and autonomous driving performance is enhanced, the demand for ultra high nickel cathode materials with maximized energy density is expected to increase significantly.

The ultra high nickel cathode material has a high nickel content, which results in relatively low thermal stability and shorter battery life. POSCO Future M has secured the required performance by using single-crystal materials, which combine major raw materials into a single particle structure, in combination with existing polycrystalline materials. Single-crystal materials have a solid particle structure with less cracking during the charge-discharge process, and structural stability is further enhanced through the addition of sub-materials and surface coating of the materials. Additionally, productivity improvements have been made to secure cost competitiveness.

The pilot development of high voltage mid nickel cathode materials for the standard electric vehicle market has also been completed. The high voltage mid nickel cathode material reduces the expensive nickel content ratio to around 60%, and solves the resulting problem of reduced energy density through high voltage. By increasing the manganese ratio and using single-crystallization, the safety can be further enhanced by minimizing contraction and expansion during charging and discharging. Furthermore, the use of non-co-precipitation precursors (precursors manufactured by omitting the co-precipitation process that mixes chelating agents and adjusters in a metal solution of major precursor raw materials such as nickel, cobalt, and manganese) during manufacturing, and reducing the ratio of expensive nickel and cobalt in the raw material composition while using cheaper lithium carbonate instead of lithium hydroxide, also enhances price competitiveness.

A POSCO Future M official stated, "Following the pilot development of ultra high nickel and high voltage mid nickel cathode materials, we plan to secure mass production technology to produce and supply them in a timely manner upon request from domestic and overseas automakers and battery companies."

one1@fnnews.com Jeong Won-il Reporter