Increased Hydrogen Production Efficiency by 6 Times Using Only an Oven Instead of a Furnace

- Input

- 2025-07-29 09:40:22

- Updated

- 2025-07-29 09:40:22

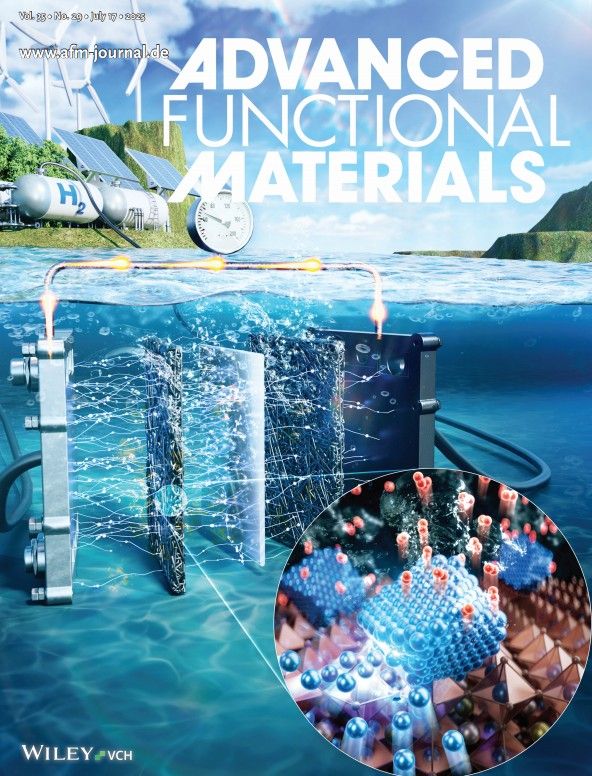

[Financial News] Recently, a domestic research team developed an innovative technology that increases hydrogen production efficiency by 6 times using only a 300℃ oven instead of a furnace exceeding 800℃. This research, conducted by Professor Kim Yong-tae and Dr. Jeong Sang-moon's team from the Department of Materials Science and Engineering and the Graduate School of Environmental Materials at POSTECH (Pohang University of Science and Technology), Professor Son Jun-woo from the Department of Materials Science and Engineering at Seoul National University, and Dr. Kim Young-gwang's team from the Department of Materials Science and Engineering at POSTECH, was published on the cover of the international journal in the materials field, 'Advanced Functional Materials', on the 17th.

According to POSTECH on the 29th, solar and wind power generation have fluctuating electricity production depending on the weather. On sunny days, there is an excess of electricity, while on cloudy days, there is a shortage. The key to solving this irregularity is 'hydrogen'. Excess electricity can be used to decompose water to produce hydrogen, which can be stored and converted back into electricity when needed.

However, there is a problem in the process of decomposing water into hydrogen and oxygen. It is easy to produce hydrogen, but the process of producing oxygen is too slow and consumes a lot of power. To solve this, a 'catalyst' that speeds up the reaction is essential. Just like cooking with high heat to boil quickly, a catalyst is needed for water decomposition to occur quickly and efficiently.

The material that the research team focused on in this study is a substance with a 'perovskite' structure. This material is noted as a catalyst because its structure is stable and its composition is easy to control, but it had limitations due to its particle size being larger than 100nm, which reduced its reactivity.

The core idea of the research team is to utilize the 'Exsolution' phenomenon. This is a phenomenon where metal ions hidden inside the perovskite spontaneously come to the surface to form nanoparticles. Previously, this process required high temperatures above 800℃ and several hours of heat treatment, but the research team succeeded in achieving the same effect at a low temperature of 300℃ using a process called 'Bead milling'.

Bead milling is a technology that applies physical impact by rotating the material with small beads. Like how laundry and washing balls collide in a washing machine to remove dirt, this process breaks down perovskite particles to below 50nm and loosens the crystal structure. This allows internal metals to move to the surface much more easily.

The newly developed catalyst increased the oxygen evolution reaction activity by about 6 times compared to existing perovskite catalysts. More importantly, by lowering the manufacturing temperature to 300℃, energy costs can be greatly saved.

Professor Kim Yong-tae stated, “This study has set an important turning point for the development of high-performance, low-cost water electrolysis catalysts," and predicted, "Precise structural control technology at the nano level will be the key to improving the efficiency of water electrolysis systems."jiany@fnnews.com Reporter Yeon Ji-an